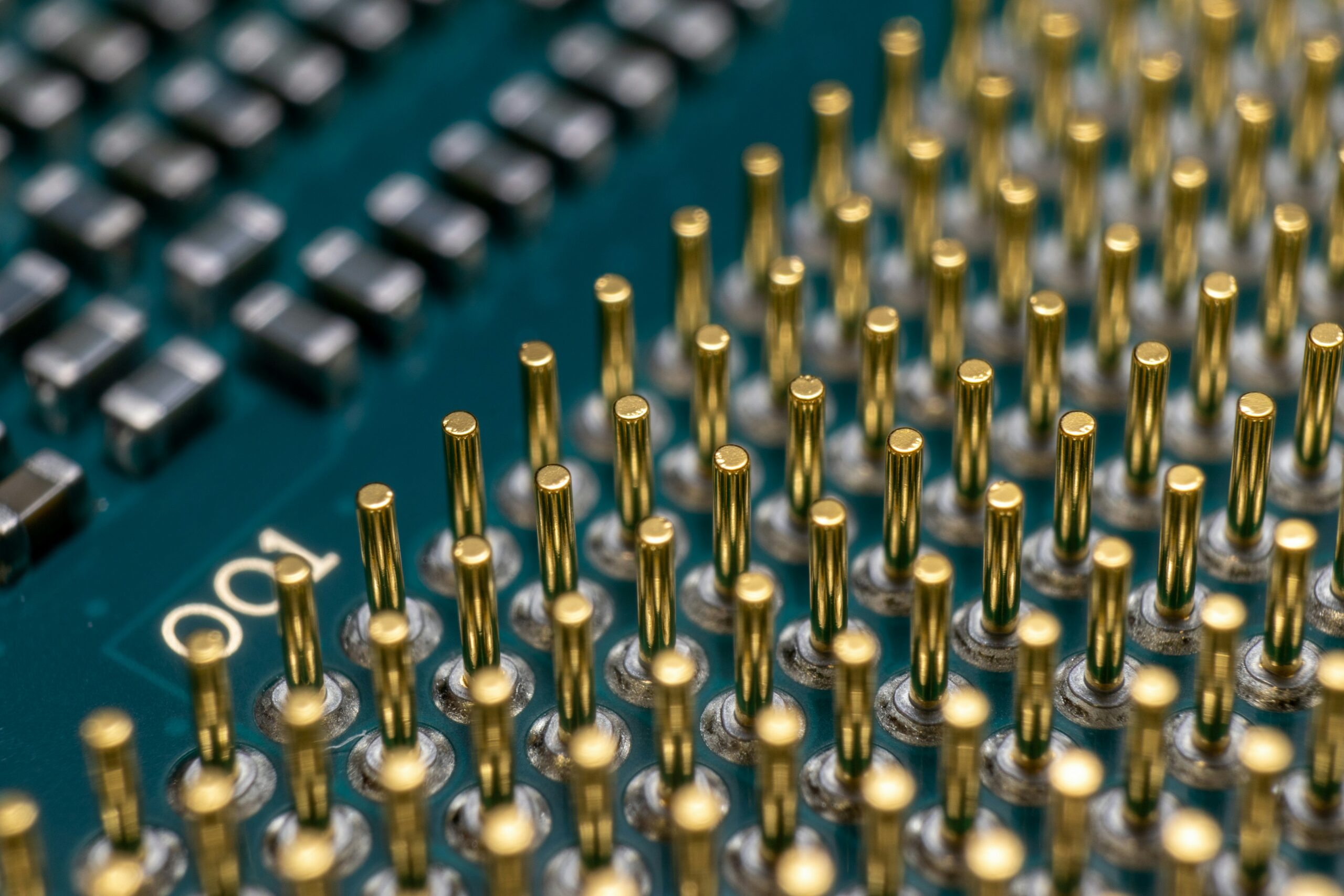

The severe, prolonged global shortage of semiconductor chips, essential components for everything from high-end smartphones to base-model household appliances, continues to choke industrial output worldwide, threatening to slow the nascent post-pandemic economic recovery and drive sustained inflation. Spanning over eighteen months, this intricate supply chain crisis—initially triggered by manufacturing disruptions and a surge in demand for personal electronics during pandemic lockdowns—has broadened its scope, now critically impacting sectors far beyond automotive manufacturing, raising fears of sustained price increases for consumers.

The Genesis of the Shortfall

The core issue stems from a profound misalignment between supply and skyrocketing demand. Modern production relies on “just-in-time” supply chains, which proved fragile when faced with unprecedented global shocks. When factories temporarily shut down or scaled back early in 2020, electronic companies, anticipating a quick rebound, massively ramped up orders for chips designed for consumer products like laptops, game consoles, and webcams. Meanwhile, automakers initially cut back on chip orders significantly, only to find themselves at the bottom of the priority list when demand for new vehicles unexpectedly rebounded later that year.

“The automotive sector, while initially the most visible victim, now represents only one facet of this systemic vulnerability,” notes Dr. Lena Khan, an economist specializing in global logistics at the Institute for Supply Chain Management. “We are seeing delays ripple across medical device manufacturing, agricultural technology, and critical infrastructure projects. The foundational digitalization of modern industry means few escape untouched.”

The bottleneck is concentrated largely in older, higher-volume chip fabrication plants (fabs) that produce the less sophisticated, yet equally critical, microcontrollers necessary for industrial operations and vehicle navigation systems. Building modern chip capacity is not a short-term solution; fully functional, high-specification fabrication facilities can take three to four years, and billions of dollars, to become operational.

Economic Fallout and Consumer Impact

The shortage has translated directly into higher costs and reduced availability for end-users. New vehicle prices have soared globally as manufacturers, unable to complete assembly, have prioritized fitting available chips into higher-margin models. For instance, reports suggest that manufacturers have, in some cases, omitted non-essential electronic features or simplified computer systems in their entry-level vehicles.

Moreover, the problem extends beyond discretionary purchases. The delay in acquiring network routers, server components, and smart grid technology slows business investment and infrastructural upgrades. This lack of essential digital inputs acts as a tax on efficiency, ultimately passing inflationary pressures downstream.

Addressing Supply Chain Resilience

Governments worldwide are increasingly treating semiconductor supply as a matter of national economic security. The European Union, the United States, and several Asian nations are offering billions in incentives to encourage domestic chip manufacturing and diversify supply geographically. The long-term goal is to build resilience, reducing reliance on the handful of East Asian manufacturers that currently dominate the market.

However, experts caution that immediate relief is unlikely. Most analysts predict that significant supply normalization—the point at which demand and capacity are reasonably balanced—will not occur until late 2023 or even 2024. Until then, businesses must continue to manage limited inventories, secure long-term purchase agreements, and potentially redesign products to use substitute components where feasible.

The current crisis serves as a stark reminder that in an interconnected world, the smallest components can exert the largest influence on global economic stability, forcing a fundamental rethink of contemporary supply chain management.